Mold division has advanced processing equipment and testing equipment. There are more than 100 sets of processing equipment, such as vertical machining center, CNC lathes, high-precision wire cutting, EDM, engraving machine, milling machine, grinding machine, high-speed punching machine, etc. There are more than 30 sets of testing equipment, such as coordinate measuring instrument X fluorescence coating thickness tester, salt spray testing machine, simple beam impact testing machine, 1T plastic tensile testing machine, etc., which can ensure the production and processing cycle and quality control of molds and products...

read more >

About us

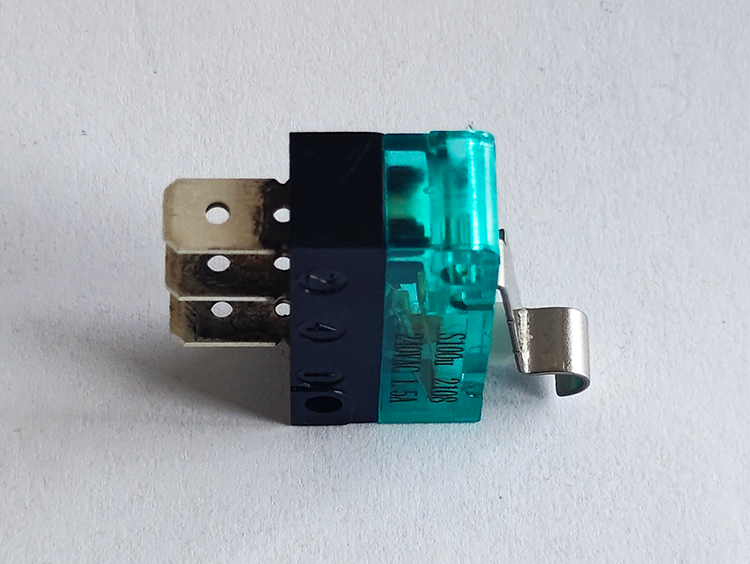

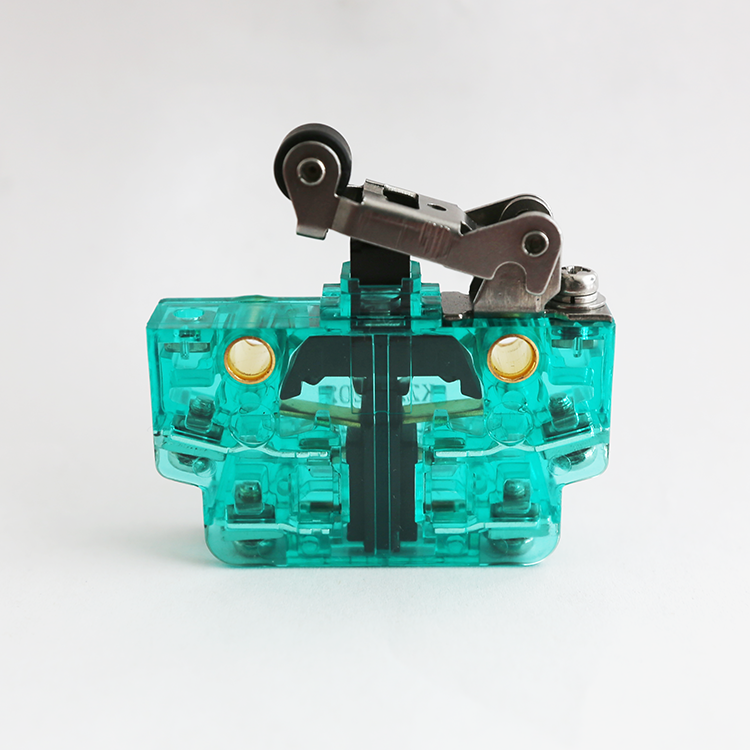

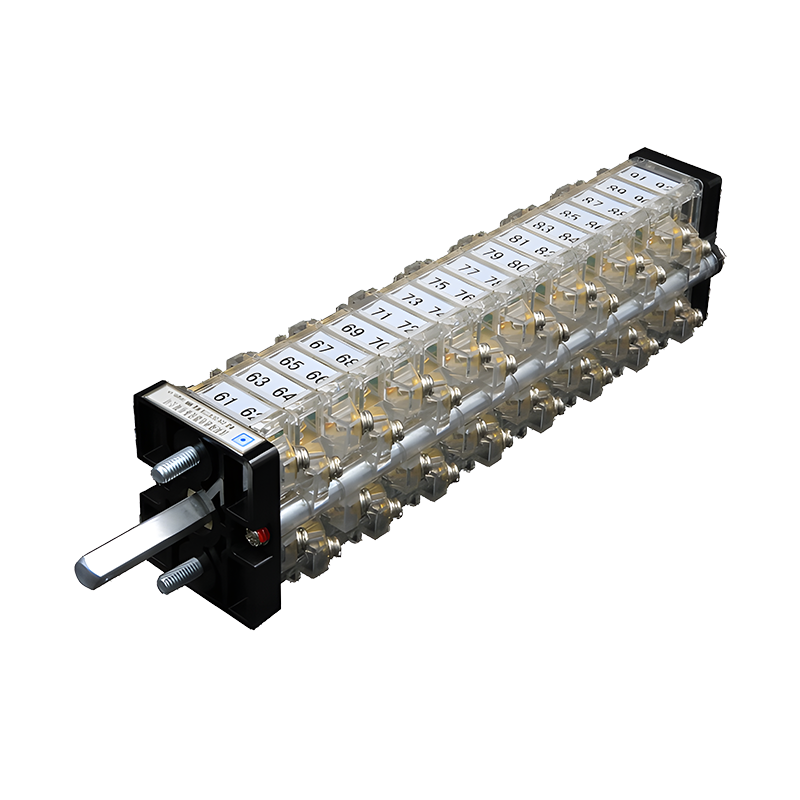

Shenyang Longdy Electrical Equipment Co., Ltd. was established in 2003, is specialized in auxiliary switch research and development, manufacturing, set stroke switch, micro switch research and development and manufacturing, precision mold design and manufacturing, precision stamping parts, plastic parts processing in one of the high-tech research and development, production enterprises.

PURPOSETo comply with truth · To work with morality

PURPOSETo comply with truth · To work with morality VISIONBuild excellent enterprises, build a hundred billion business circle, and help the northeast economy

VISIONBuild excellent enterprises, build a hundred billion business circle, and help the northeast economy MISSIONTo create a rich and happy life for employees, at the same time, to contribute to the development of customers and society.

MISSIONTo create a rich and happy life for employees, at the same time, to contribute to the development of customers and society. SENSE OF WORTHActively love life and work, to be rigorous, honest, grateful, humble and altruistic.

SENSE OF WORTHActively love life and work, to be rigorous, honest, grateful, humble and altruistic.PRODUCT CENTER

Business Partner

News Information

The Role of Microswitches in Division Controllers

In today's era of rapid development of precision control and automation technology, each subtle component plays an indispensable role. Among them, microswitches, as a bridge connecting physical operation and electronic signal conversion, play a pivotal role in the key equipment of the Division Controller. In this article, we will discuss the core functions and advantages of microswitches and their important contribution to enhancing system performance.

read more >

Features and benefits of cam-type auxiliary switches

In modern electrical control systems, cam-type auxiliary switches have become the first choice in many areas of industrial automation and machinery and equipment control due to their unique design and excellent performance. These switches are not only highly accurate and reliable, but also have a wide range of applications and significant advantages. In this paper, we will discuss the characteristics and advantages of cam-type auxiliary switches and reveal their value in practical applications.

read more >

Operating environment analysis of microswitches: key factors and optimisation strategies

In the vast world of electronic components, microswitches have become indispensable components in many precision devices and complex circuits due to their compactness, delicacy, sensitivity and reliability. However, in order to ensure the long-term stable operation of microswitches, it is crucial to deeply analyse their working environment and take corresponding optimization measures. This article will focus on the core theme of ‘micro switch operating environment analysis’, from the temperature, humidity, vibration, electromagnetic interference and other dimensions to explore, aiming at engineers and technicians to provide valuable reference.

read more >