Mold Manufacturing Division

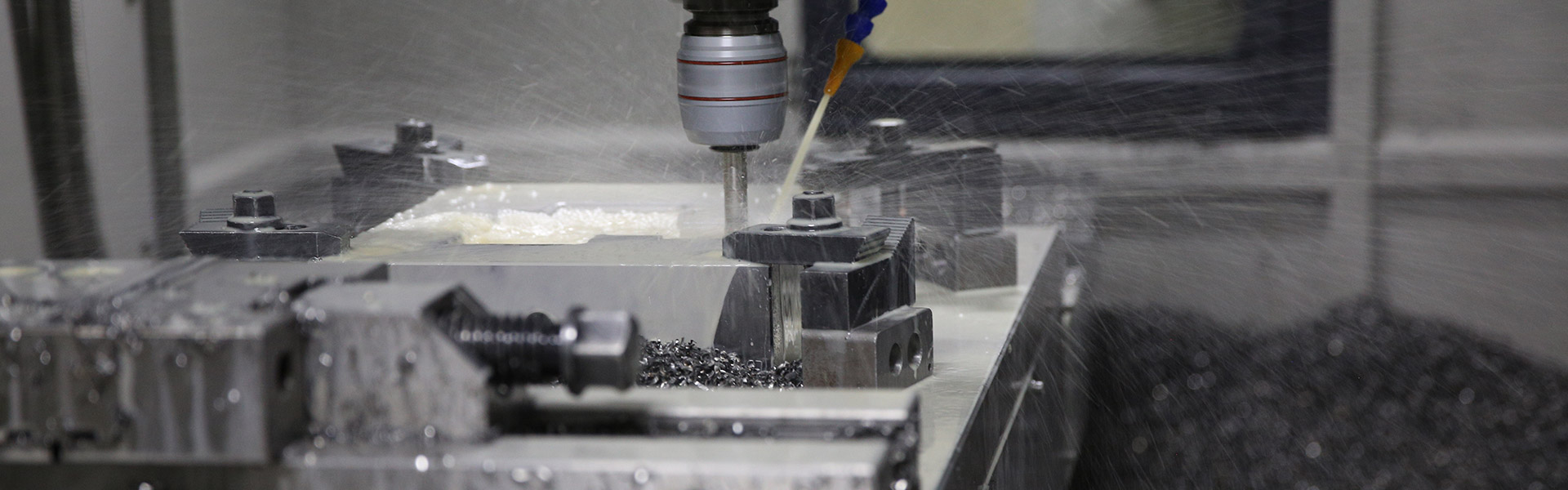

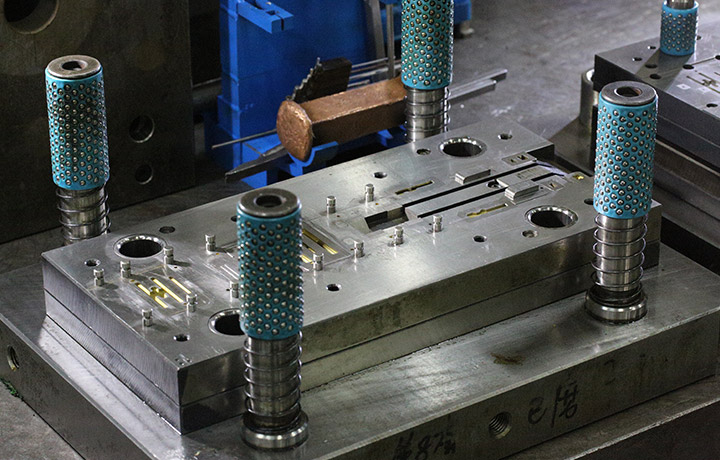

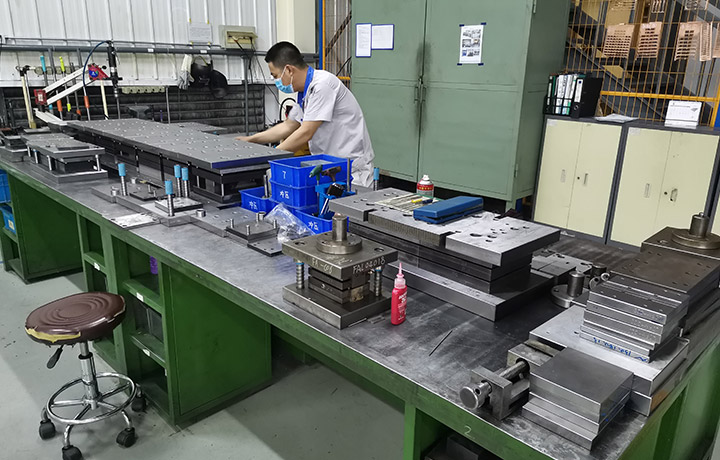

The division has advanced processing equipment and testing equipment. The processing equipment has more than 100 sets of vertical machining center, CNC lathe, high precision wire cutting, electric spark, fine engraving machine, matte machine, grinding machine, high-speed punching machine, etc. There are more than 30 sets of testing equipment, such as coordinate measuring instrument, X-ray fluorescence coating thickness tester, salt spray testing machine, simple beam impact testing machine, 1T plastic tensile testing machine, etc., which can ensure the production and processing cycle and quality control of mold and products.

At the same time, the division has many years of professional design personnel engaged in mold development and mold manufacturing and maintenance technicians, foreign to undertake Haier, Panasonic battery and other well-known customers mold development, manufacturing and maintenance services. At the same time for the electrical switch industry to provide a variety of, multi-specification injection molding and metal parts.