In the processing of automobile stamping parts, it is necessary to carry out multi-channel punching, cutting, bending, drawing and other processes to achieve the deformation and forming of metal materials. First of all, the designer will draw the corresponding stamping drawings according to the design needs and functional requirements of the car. Then, through the use of punches, cutting machines, bending machines and other professional equipment, the metal material stamping, cutting, bending and other processing processes. Ultimately, the raw material is processed into shaped stamping parts for the assembly of the car.

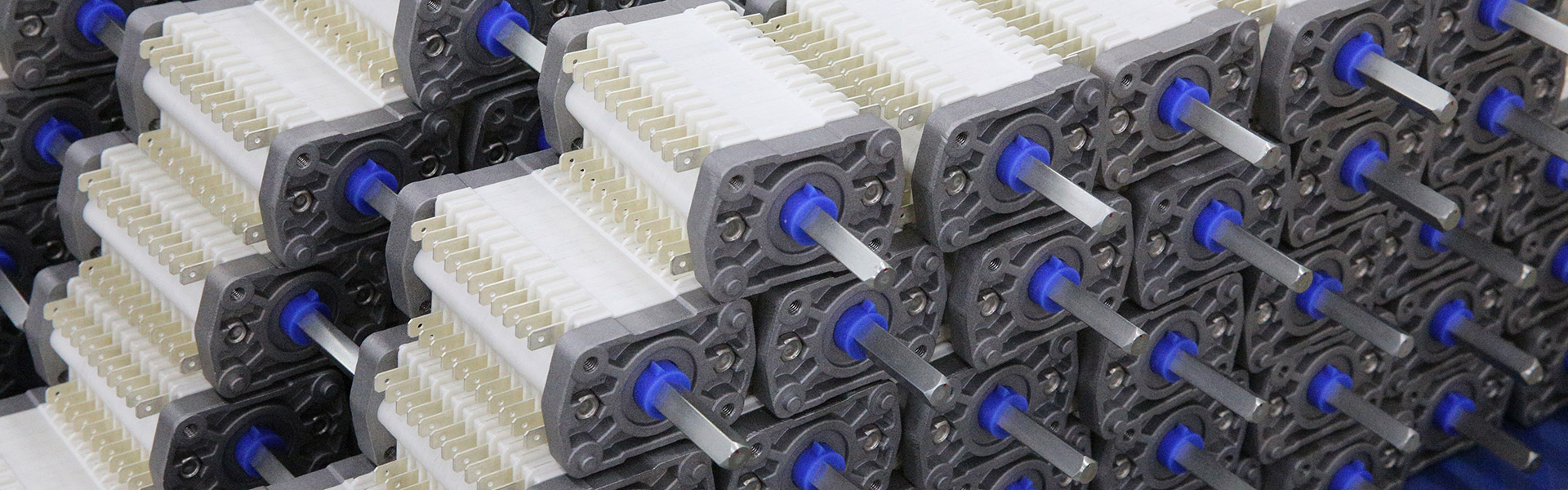

Product profile

Automotive stamping parts processing is a comprehensive technology, first of all, the choice of materials for the quality and performance of stamping parts play an important impact. Common stamping materials include steel, aluminum alloy and stainless steel, etc. Different materials have different mechanical properties and corrosion resistance, so it is necessary to choose the right material according to the requirements. Secondly, the selection and operation of mechanical equipment is also crucial to the effect and quality of stamping parts processing. Punch press is a commonly used stamping equipment, which can provide enough impact force and stable processing speed to ensure the accurate shape and size of the stamping parts. In addition, it is also necessary to pay attention to the maintenance and maintenance of the equipment to extend the service life of the equipment and ensure the quality of processing. Process technology also plays a decisive role in the processing of automotive stamping parts. Different stamping processes will affect the forming effect and quality of stamping parts.