Stamping processing, as the name suggests, is the process of processing metal materials through stamping equipment. It uses the punching machine to impact, stretch, bend and other deformation operations on the metal material through the mold, so as to obtain the required parts. Stamping processing has the characteristics of high efficiency, high precision and good repeatability, and is widely used in the field of industrial manufacturing.

Product profile

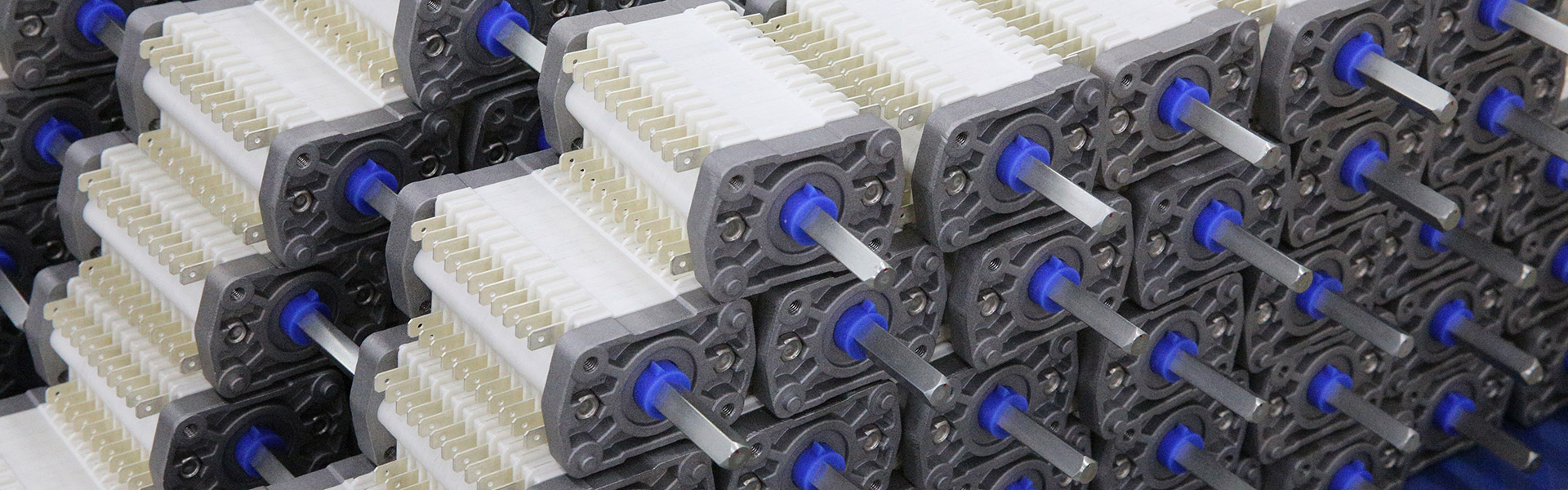

Stamping process relies on the role of the mold to plastic deformation of metal materials. Die is the core tool of stamping processing, it includes the upper die and the lower die two parts, through the impact, pressure and other effects to make the metal material plastic deformation, and finally get the required product. The principle of stamping is complex and changeable, involving material mechanics, metal forming and other disciplines. The process flow of stamping processing generally includes: design drawings → manufacturing molds → debugging molds → material cutting → forming processing → quality testing → product packaging. Different products correspond to different process flows, which need to be designed and adjusted according to actual production needs. Stamping is widely used in many industries. In the field of automobile manufacturing, stamping processing is used to manufacture body parts, doors, engine hoods and other structural parts; In the field of home appliance manufacturing, stamping processing is used to manufacture refrigerator doors, washing machine shells, etc. In the electronics industry, stamping is used to make mobile phone cases, keyboards and other devices. It can be said that stamping processing plays an indispensable role in modern industrial manufacturing.