Craftsmanship: the art and precision of automotive stamping parts processing

Release time:2024-03-28

In the wheel of modern industry, the automobile manufacturing industry is a bright pearl, and in this radiant industry, automobile stamping parts processing is an indispensable precision technology. It is like a delicate carving, each stroke is related to the safety and performance of the car, each knife is cohesive with the wisdom and sweat of the craftsmen. Today, let's explore the process requirements behind this art and feel those unknown details and persistence.

First of all, automotive stamping parts processing is extremely careful about the choice of materials. Steel, as the most commonly used material, its hardness, toughness, ductility must meet stringent standards. This is not only to ensure the stability of the stamping parts in the molding process, but also to ensure that the final product can withstand various stresses in the car driving without deformation or fracture. Every choice of material is a promise of future safety.

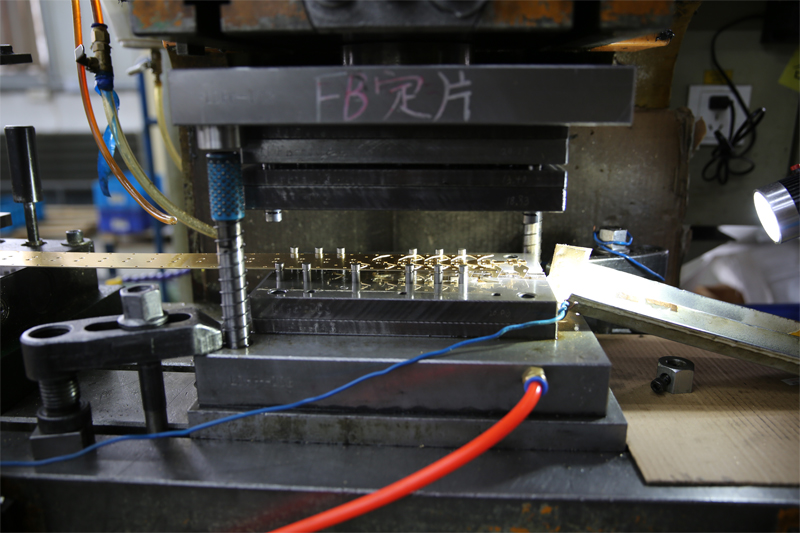

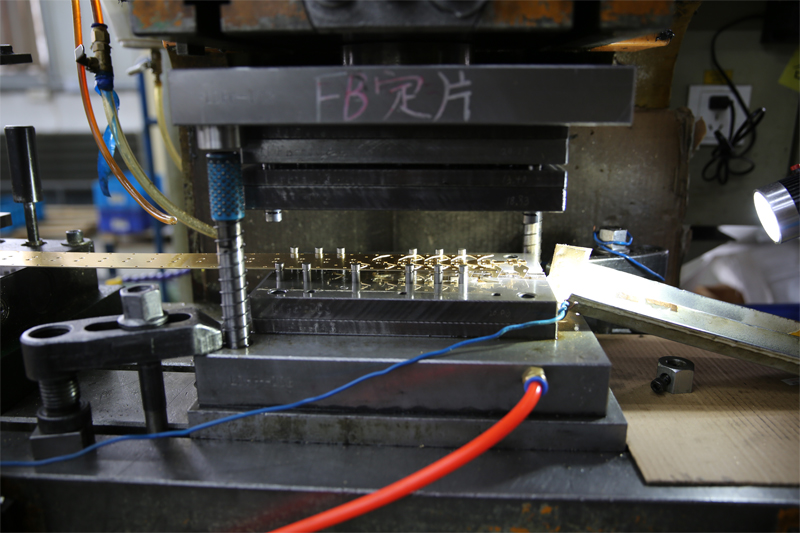

Next, precision is the soul of automotive stamping parts processing. With every stamping, the dimensions of the part must be guaranteed to be precise and accurate. This is not just a millimeter-level competition, but also the pursuit of perfection. Because any tiny deviation may affect the performance of the whole car and even the life safety of the driver. Therefore, high-precision mold design and manufacturing, strict machine calibration, as well as fine operating procedures are all indispensable links.

Furthermore, temperature control during the processing of automotive stamping parts is also crucial. Metals have different properties at different temperatures, and the temperature at which stamped parts are processed directly affects the plasticity and fluidity of the material. Too low a temperature may lead to material cracking, while too high a temperature may cause excessive softening and affect the strength of the finished product. Therefore, precise temperature control technology is the cornerstone to ensure that every stamped part meets the design requirements.

In addition, lubrication is also a part of automotive stamping parts processing that cannot be ignored. Proper lubrication can reduce the friction between the mold and the material, extend the service life of the mold, and also improve the surface quality of the finished product. In the choice of lubricant, not only to take into account its lubrication effect, but also to pay more attention to its impact on the material and the environment.

Finally, quality control is the top priority in the automotive stamping parts processing process. From the inspection of raw materials to the factory of finished products, there is a strict quality control system for each link. This includes not only visual inspection and dimensional measurements, but also multiple testing methods such as mechanical property tests to ensure that every product meets or even exceeds industry standards.

Behind this seemingly cold process is the immense respect for life safety, the relentless pursuit of industrial aesthetics, and the ultimate obsession with details. In short, the choice of materials for processing plastic parts for electrical appliances is a science and an art. It requires us to pursue beautiful and practical at the same time, not forgetting the responsibility for the environment and the future.

Let's look forward to, through careful material selection and innovative design concepts, electrical plastic parts will continue to play an important role in our lives, how in this ever-changing world, shaping a better future. [...] [...]

First of all, automotive stamping parts processing is extremely careful about the choice of materials. Steel, as the most commonly used material, its hardness, toughness, ductility must meet stringent standards. This is not only to ensure the stability of the stamping parts in the molding process, but also to ensure that the final product can withstand various stresses in the car driving without deformation or fracture. Every choice of material is a promise of future safety.

Next, precision is the soul of automotive stamping parts processing. With every stamping, the dimensions of the part must be guaranteed to be precise and accurate. This is not just a millimeter-level competition, but also the pursuit of perfection. Because any tiny deviation may affect the performance of the whole car and even the life safety of the driver. Therefore, high-precision mold design and manufacturing, strict machine calibration, as well as fine operating procedures are all indispensable links.

Furthermore, temperature control during the processing of automotive stamping parts is also crucial. Metals have different properties at different temperatures, and the temperature at which stamped parts are processed directly affects the plasticity and fluidity of the material. Too low a temperature may lead to material cracking, while too high a temperature may cause excessive softening and affect the strength of the finished product. Therefore, precise temperature control technology is the cornerstone to ensure that every stamped part meets the design requirements.

In addition, lubrication is also a part of automotive stamping parts processing that cannot be ignored. Proper lubrication can reduce the friction between the mold and the material, extend the service life of the mold, and also improve the surface quality of the finished product. In the choice of lubricant, not only to take into account its lubrication effect, but also to pay more attention to its impact on the material and the environment.

Finally, quality control is the top priority in the automotive stamping parts processing process. From the inspection of raw materials to the factory of finished products, there is a strict quality control system for each link. This includes not only visual inspection and dimensional measurements, but also multiple testing methods such as mechanical property tests to ensure that every product meets or even exceeds industry standards.

Behind this seemingly cold process is the immense respect for life safety, the relentless pursuit of industrial aesthetics, and the ultimate obsession with details. In short, the choice of materials for processing plastic parts for electrical appliances is a science and an art. It requires us to pursue beautiful and practical at the same time, not forgetting the responsibility for the environment and the future.

Let's look forward to, through careful material selection and innovative design concepts, electrical plastic parts will continue to play an important role in our lives, how in this ever-changing world, shaping a better future. [...] [...]