The metal sheet is formed into various special-shaped parts according to specific drawing requirements by punching machine. Compared with traditional parts processing, shaped parts stamping has many unique advantages. It can achieve large-scale production and improve production efficiency. Can ensure the accuracy and consistency of parts. Through the use of advanced mold technology, we can ensure that the size and shape of each part meet the requirements, reducing the human error in the traditional processing process.

Product profile

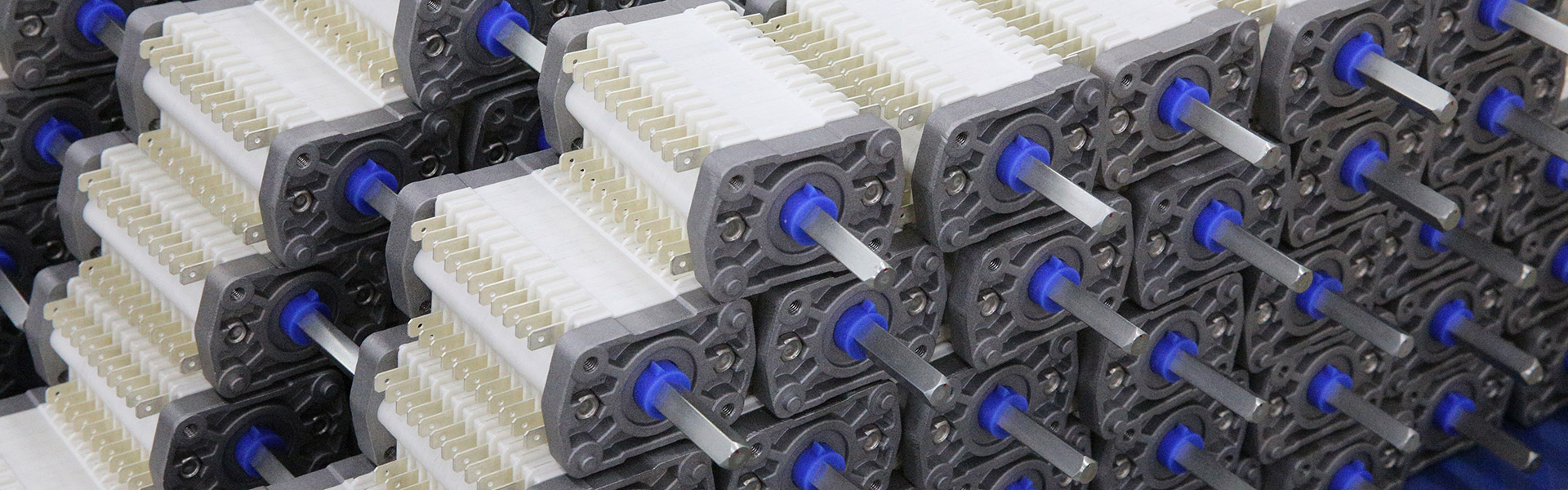

Shaped parts stamping processing is widely used in automotive, home appliances, communications, construction and other industries. Taking the automotive industry as an example, stamping parts are one of the important structural components of automobiles. Automobile exterior panel, body support, doors, hood and other parts can be manufactured by stamping process, which can not only improve the assembly accuracy and quality of products, but also reduce production costs. In the home appliance industry, shaped parts stamping can produce a variety of shells, panels and other parts, adding a sense of beauty and fashion to the product. In the communications industry, stamping can produce parts such as mobile phone cases and electronic product shells to improve the pressure resistance and durability of products. In the construction industry, stamping processing can make aluminum alloy doors and Windows, sunlight rooms and other diversified special-shaped components, providing more design flexibility for construction enterprises.