Toy injection molding processing is an important link in the modern toy industry. Through injection molding, ideas can be turned into reality and a variety of toys with unique shapes and rich colors can be produced.

Product profile

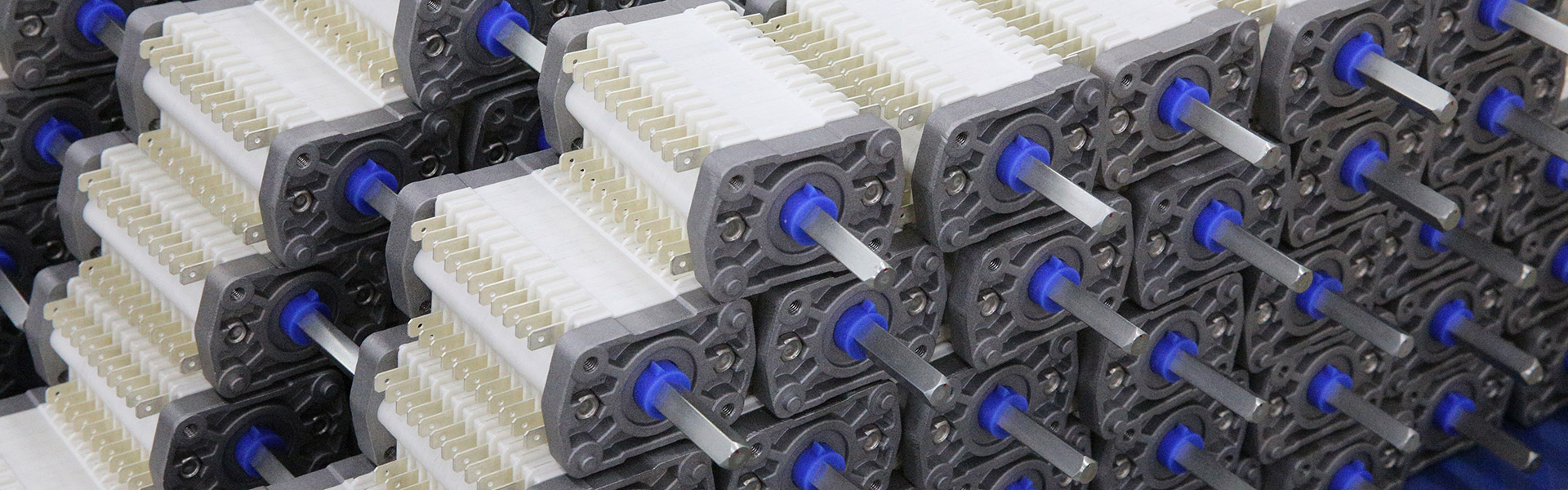

The process flow of toy injection molding includes raw material preparation, injection molding, painting and polishing. First of all, you need to select suitable raw materials. Common plastic materials include polyethylene, polypropylene and other plastic materials. Next, after the raw materials are heated to a molten state, they are injected into the mold through an injection molding machine. After the plastic cools, it is taken out to obtain the initial toy prototype. Finally, surface treatment processes such as painting and grinding are carried out to make the toy look more refined.