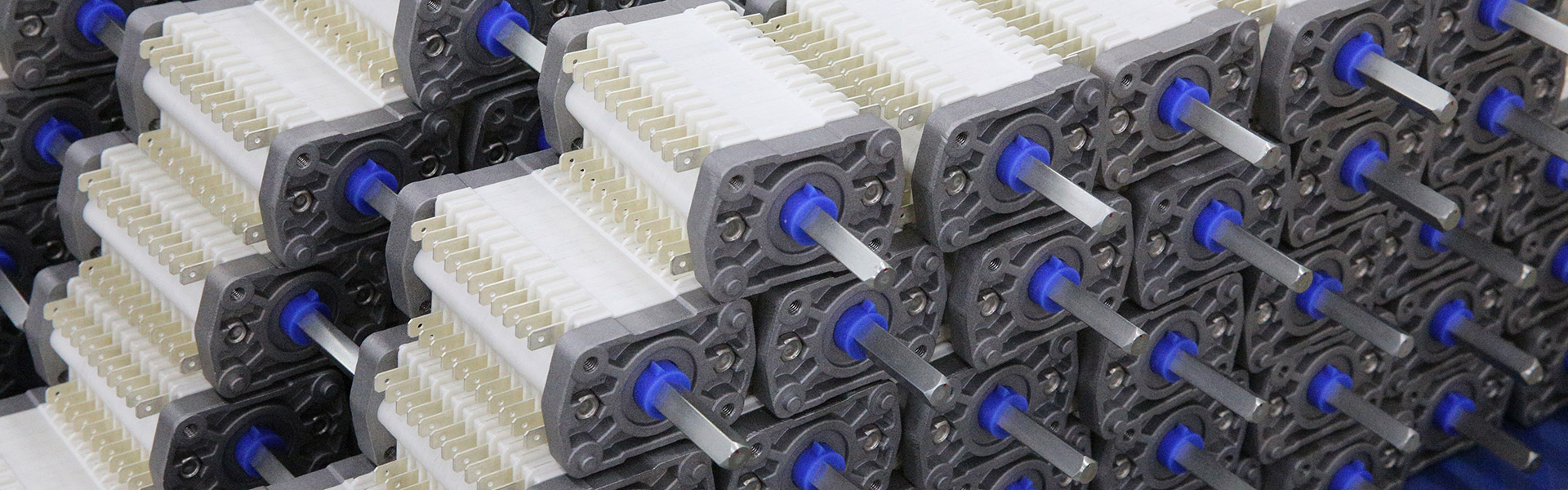

Product profile

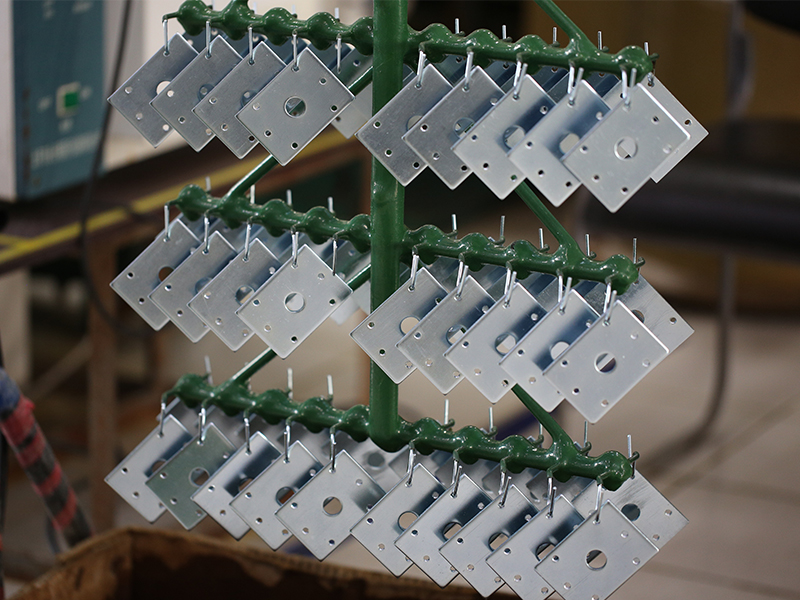

The galvanizing process can be divided into several stages: first the preparation of the metal surface, then the galvanizing process, and finally the surface treatment after galvanizing. This treatment can protect the base metal from corrosive substances such as acids, caustic alkalis, and gases. When the galvanized layer is scratched, the zinc can easily sacrifice its anode to protect the base metal from rusting.

There are many methods of galvanizing, including hot-dip galvanizing, electro-galvanizing and mechanical galvanizing. Among them, hot-dip galvanizing is to immerse the rust-removed steel parts into molten zinc liquid at about 500°C, so that a zinc layer is attached to the surface of the steel components. Cold galvanizing involves degreasing, pickling, dipping, and drying the workpiece, then immersing it in the molten zinc solution for a certain period of time and then lifting it out. Compared with hot-dip galvanizing, mechanical galvanizing has a simpler process and lower cost.