Stamping die is a special process equipment that processes materials (metal or non-metal) into parts (or semi-finished products) in cold stamping processing, called cold stamping die (commonly known as cold stamping die). Stamping is a pressure processing method that uses a die mounted on a press to apply pressure to the material at room temperature to produce separation or plastic deformation, so as to obtain the required parts.

Product profile

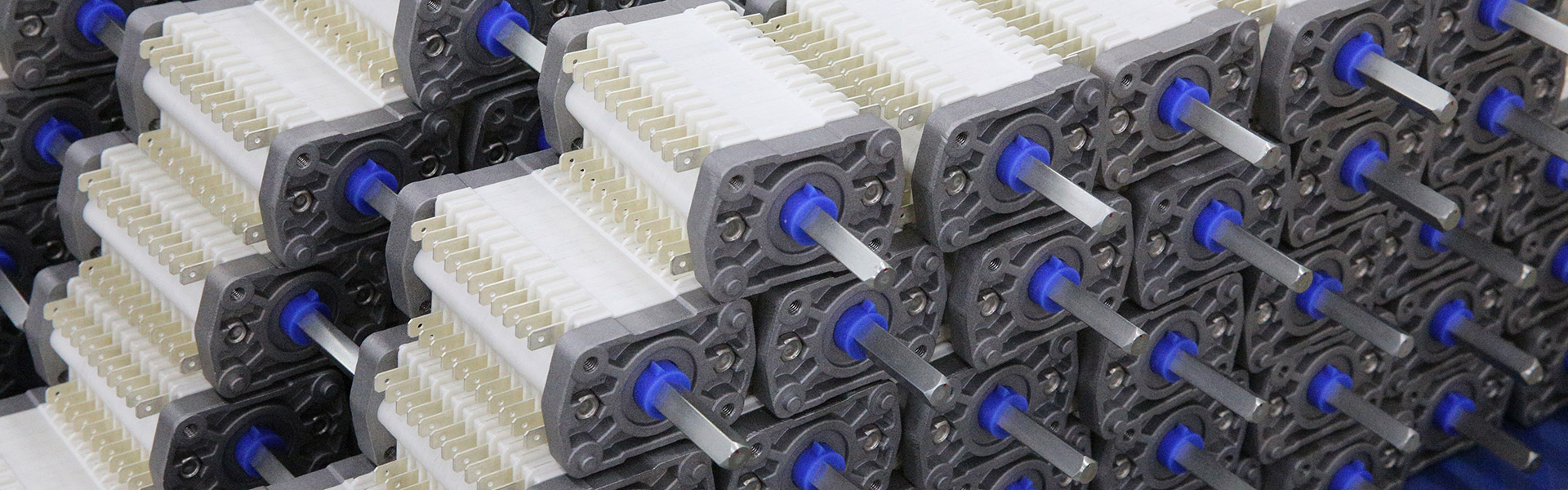

Stamping die is an indispensable key equipment in the stamping process, which is widely used in various fields such as automobiles, home appliances, electronics, aviation and so on. Different stamping dies can achieve different forming effects, so as to meet the production needs of various products. This article will introduce the types of stamping dies and the application of various dies in detail, and take you to a comprehensive understanding of the world of stamping dies.

A, simplex mold

Simplex die is the most basic and most commonly used form of stamping

die. It is composed of upper die, lower die and guide member, simple and

easy to operate. In the production, the simplex die is mainly used for

parts blanking, forming and shaping processes. Although the function of

the simplex mold is relatively single, it has a wide range of

application and low cost, so it is still the first choice of many

enterprises.

Two, composite mold

The composite die is

also called a multi-station die, which is composed of a number of

working parts, and each working part can complete different stamping

processing tasks. Compared with the simplex die, the composite die has

the advantages of high production efficiency and low production cost.

The composite die is suitable for the multi-process requirements of the

same part, and multiple processes can be completed in a single stamping

operation, greatly improving the production efficiency.

Three, continuous mold

Continuous die is the advanced form of stamping die, which can realize

continuous stamping process. It realizes continuous automatic production

through continuous blanking, continuous stamping and continuous

discharge and other process steps. Continuous mold is suitable for mass

production, which can greatly improve production efficiency and product

quality, and is favored by many enterprises.

Four, special mold

In addition to the above three basic stamping molds, there are many

special molds, such as bending molds, drawing molds, punching molds,

etc. These molds play an important role in specific production

processes. For example, a bending die is used to bend a metal material

into a desired shape; Tensile dies can stretch metal materials into

thin-walled structures. The special mold is designed according to the

different needs of the product, which can achieve more complex and fine

processing.

Stamping die has a wide range of applications. In

the field of automobile manufacturing, stamping dies are used in the

production of automobile body, doors, hood and other parts; In the home

appliance industry, stamping dies are used for the manufacture of key

components such as home appliance shell and transmission system; In the

electronics industry, stamping molds are used for the processing of

various products such as mobile phone cases and computer shells. It can

be said that stamping die is an indispensable tool for modern industry.