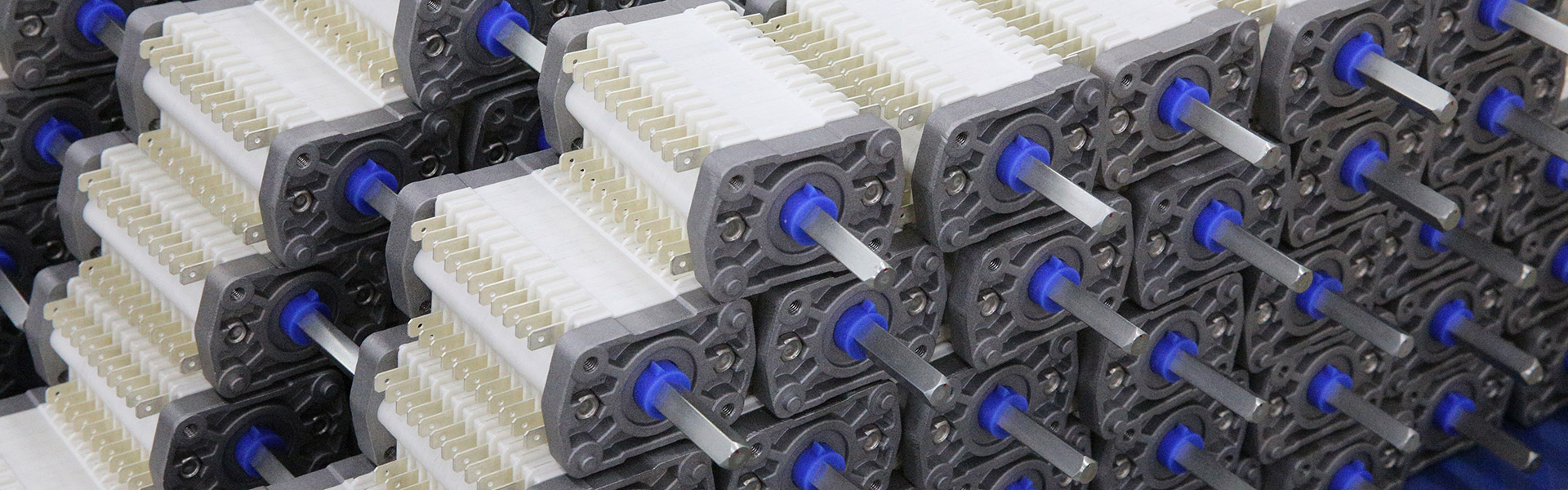

Product profile

1. Composition of injection mold

Injection molds generally consist of an injection mold body, a mold base, a mold positioning system, a nozzle adjustment system, and mold accessories. Among them, the injection mold body is the most important part, and its design needs to consider factors such as the size, shape, quantity, accuracy, and surface quality of the molded parts.

2. Selection of injection mold materials

The choice of injection mold material directly affects the service life and cost of the mold, so it needs to be chosen carefully. In general, commonly used materials for injection molds include tool steel, alloy aluminum, copper alloy, plastic, etc. The specific selection should be determined based on the design requirements and production needs of the mold.

3. Design requirements for injection molds

During the design process of injection molds, the structure and requirements of the parts need to be fully considered to ensure the accuracy and stability of the mold design. In addition, the design of injection molds also needs to consider aspects such as cost, maintainability and repairability to meet production and maintenance needs.