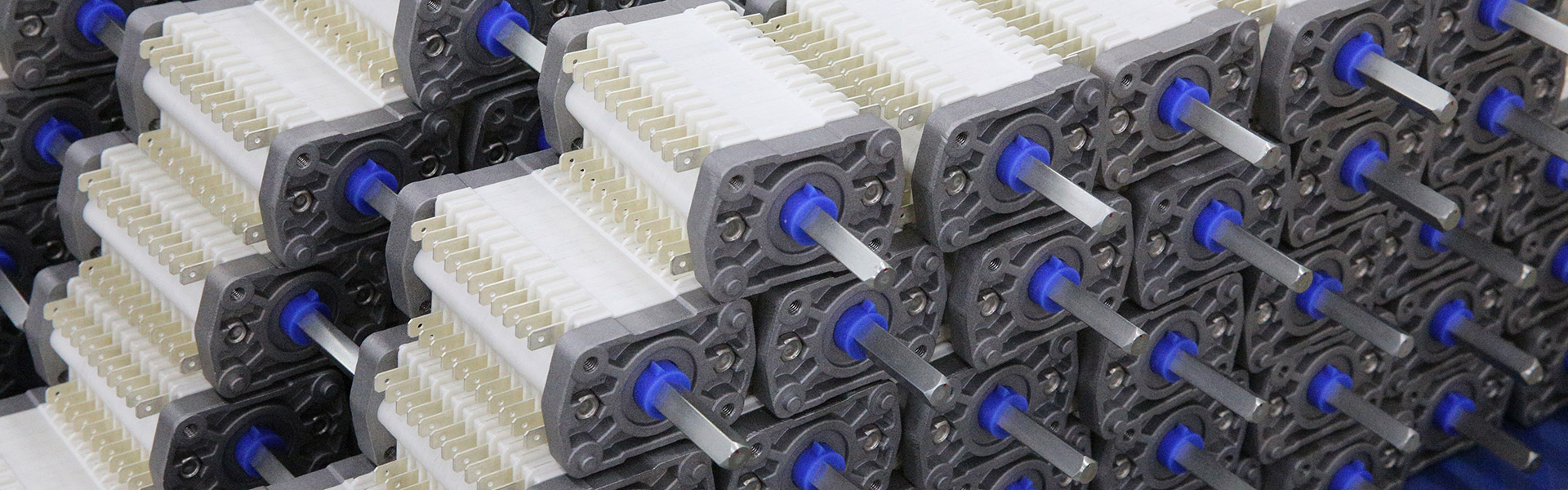

Stamping parts processing is to use sheet metal as raw materials, through the mold and stamping equipment to carry out a series of processing processes, and finally get the parts that meet the requirements. This processing method can not only achieve mass production, but also meet the strict requirements for product quality and appearance. Common stamping parts include mobile phone shell, car body parts, home appliance shell and so on.

Product profile

The process of stamping parts processing usually includes design, mold manufacturing, material preparation, stamping processing and subsequent processes. First, design according to product requirements and determine the type of mold required. Subsequently, the mold is manufactured, including selecting the appropriate mold material, designing the mold structure and machining the parts. In the material preparation stage, the appropriate metal sheet needs to be selected and cut and formed according to the product requirements. The stamping process stage is the most critical step in the entire process, requiring the mold to be precisely matched with the stamping equipment to press the sheet metal into the desired shape through the impact force. Finally, surface treatment, assembly and quality inspection of stamping parts are carried out.